|

|

||||||||||

| Адрес:107023, г. Москва, Барабанный переулок, дом 4, стр 6, БЦ «На Барабанном» e-mail: info@sforp.ru Тел.: (495) 988-61-46 |

Выпуск №66 15.02.2021 Выпуск №65 29.12.2020 Выпуск №62 21.09.2020 Выпуск №59 18.11.2019 Выпуск №57 24.06.2019 Выпуск №52 09.07.2018 Выпуск №50 01.02.2018 Выпуск №49 27.12.2017 Выпуск №48 27.11.2017 Выпуск №47 13.11.2017 Выпуск №46 4.09.2017 Выпуск №44 14.06.2017 Выпуск №43 13.03.2017 Выпуск №41 03.10.2016 Выпуск №40 30.08.2016 Выпуск №39 07.07.2016 Выпуск №38 28.03.2016 Выпуск №37 17.03.2016 Выпуск №36 24.02.2016 Выпуск №35 28.01.2016 Выпуск №32 09.11.2015 Выпуск №31 08.10.2015 Выпуск №29 30.07.2015 Выпуск №28 24.06.2015 Выпуск №27 07.05.2015 Выпуск №26 03.04.2015 Выпуск №24 25.02.2015 Выпуск №23 03.02.2015 Выпуск №22 23.12.2014 Выпуск №21 04.12.2014 Выпуск №20 06.11.2014 Выпуск №19 07.10.2014 Выпуск №18 04.09.2014 Выпуск №16 30.06.2014 Выпуск №15 05.05.2014 Выпуск №14 31.03.2014 Выпуск №13 11.03.2014 Выпуск №12 23.01.2014 Выпуск №11 26.12.2013 Выпуск №10 29.11.2013 Выпуск №9 14.10.2013 Issue #8 27.08.2013 Business-Inform News Russian Suppliers News Teko Prisma MPS-project – Modern Printing Monitoring Using Nubeprint System Выпуск №7 19.08.2013 Выпуск №6 01.07.2013 Выпуск №5 16.05.2013 Выпуск №4 24.04.2013 Выпуск №3 26.03.2013 Выпуск №2 20.02.2013 | Teko Prisma MPS-project – Modern Printing Monitoring Using Nubeprint System Sofinskaya Tatiana (TEKO, Russia)

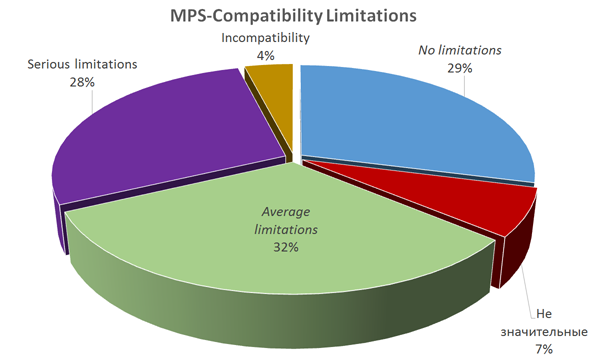

Managed Print Service means active document workflow, equipment, and related business-processes control, as well as their optimization. This is a definition given to this type of service by International MPS Association. It implies that clients, who have chosen printing outsourcing, can no longer worry themselves about equipment and supplies. They only pay for copies they have printed. Also by relaying office printing to another company, the customers expect that all the tasks related to it will be performed without their participation. By becoming MPS-provider, the service company takes on a responsibility of optimizing client’s printing environment and guaranteeing that the client’s spending won’t be growing. By doing this it limits the growth of its own revenue. The only way to retain profitability is to cut the costs. The optimal way to achieve it is to reduce man-hours. That can be done by automated information collection from the equipment, its analysis, and building more effective processes based on it. MPS service cannot exist without an information collecting tool, because if you just want to present your customer with a bill, you must know, who has been printing and how many pages have been printed. The data can be either collected manually (which is quite costly), or that can be done automatically. The solution for the second variant can be found in DCA (Data Collection Agent). It is created to collect data from the devices without human intervention, and is a basic instrument to work with MPS project. Unfortunately many devices have various limitations for remote monitoring. That is why different data collecting instruments can present MPS provider only with information about counters, and that sufficiently limits the range of usage for those instruments. While working on its Prisma project Teko Company has chosen Nubeprint system for printing monitoring. This is a unique solution created by Spanish developers. It incorporates more than 10 years of successful work with MPS contracts, where the tasks were – maximum automated data collection about the equipment being serviced, and reducing the number of addresses by users due to proactive work processes. The instrument is based on intellectual mechanism, which tries to compensate for the lack of information by taking into consideration the characteristics of every device. Based on the analysis of more than 1,300 equipment models used currently in the offices, “MPS-compatibility” index1 was built. It turned out that 71% of devices have various limitations. However, new approaches allow to overcome them.

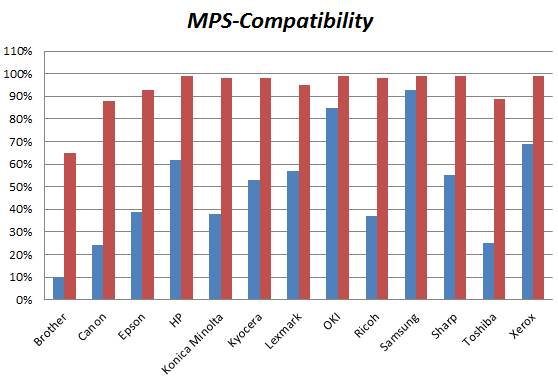

One of the key characteristics of Prisma DCA is the system of virtual toner-level deducting (VLS). In cases when the printing device is unable to present the data concerning toner or ink level, the system gives its own forecast based on statistical model. The forecast becomes more and more precise with every cartridge replacement. The same mechanism allows to work correctly with most compatible supplies.  The blue bars on the chart show the initial MPS compatibility, the red bars show the MPS-Compatibility after switching to Prisma DCA. Here are only some of the tasks, which can be solved with Prisma DCA:

As a result of using Prisma DCA you can achieve the following savings:

Besides, the system is easy in use. It is easily installed and does not require administrator’s rights for launching. Prisma DCA can work in distributed system and meets the harsh security standards. The proof is the compliance with many international standards. The software is an open source type, which allows for audit of all processes, it can be used in offices, where under the security measures the direct Internet contact is prohibited, via setting up of mail-server data exchange. This way, Prisma monitoring system can be called optimal, because its usage allows operative and most complete data gathering concerning customer’s printing fleet, including the devices that are poorly compatible with MPS. It allows the automatization of the majority of MPS-provider working processes, and consequently cutting of the costs.

|

|

|||||

|

|

|||||

|

|

In English

In English